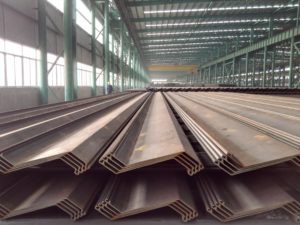

Lassen steel sheet pile in deep foundation pit

1.0 Advantages of Lassen steel sheet pile:

(1) Convenient operation, which helps shorten the construction period.

(2) Low cost and reusable.

(3) Excellent performance under forces, which helps saves material.

(4) The number of earthworks and backfill of pile caps has significantly been reduced, which protects land resources and increased environmental efficiency.

2.0 Construction flow of deep foundation pit platform

The construction process is as follows:

Preparation before construction → Insertion of Lassen steel sheet pile → Completion of the support structure and excavation construction sealing → Structural construction → Cap Backfilling → Removal of Lassen steel sheet pile

(1) Prepare site, remove obstacles, and set the survey out.

(2) Transport Lassen steel sheet pile and driving equipment to the construction site.

(3) Insert 12 MSP – Ⅳ Lassen steel sheet pile. Install special equipment (mechanical arm) in Crawler hydraulic excavator. Each Lassen steel sheet pile interlock each other to form a sealing barrier.

(4) Cofferdam support and excavation: excavate and construct two layers of enclosing purlins. The excavation uses 200 type backhoe excavator with a long arm, and the earthwork should be transported out in time.

(5) Base sealing: the back sealing takes 20cm C15 concrete.

(6) Pour concrete on the platform.

(7) Backfill the cushion cap.

(8) Use vibration hammer to remove Lassen steel sheet pile.

3.0 Quality control of Lassen steel sheet pile construction

3.1 Lassen steel sheet pile cofferdam construction

Steel sheet pile cofferdam construction takes crawler hydraulic vibration pile driver to insert and remove steel sheet pile.

Construction process:

Preparation → Insertion of steel sheet pile cutting → Excavation (elevation 1.5m) → Construction of enclosing purlin in the first layer and support structure → Excavation → Construction of enclosing purlin in the second layer → Excavation to bottom elevation → bottom sealing.

3.1.1 Preparation before driving steel sheet pile

Site levelling and compaction.

The steel sheet pile may appear collision, bending and torsion and lock deformation after loading, unloading, and transportation. Under this case, steel sheet pile must be checked before assembling to eliminate the lock crack, distortion and deformation of steel sheet pile. In addition, butter is taken to reduce the friction between the locks and the leakage of the steel sheet pile cofferdam.

3.1.2 Insertion steel sheet pile

(1) Insertion of gauge pile.

The position of the gauge pile is determined by the total station. Before each section of construction, two gauge pile are driven into each side with vibration hammer.

(2) Insertion of steel sheet pile.

Steel sheet pile is driven under the reference of the positioning pile. At this time, theodolite is used to observe in two perpendicular directions to ensure that steel sheet piles are inserted in a correct direction.

If there is any mistake in assembly, chain reversing or pulley group should be used to assemble, and after assembly, each one should be driven to the design depth.

(3) Assembly.

① The preparation before assembly.

When it is about to close, the straight-line distance at the bottom of the steel sheet pile is measured and calculated. Also, the number of required steel sheet piles is calculated based on the width of the steel sheet pile. Then, the way how to insert and play the steel sheet in the next step is determined (whether to increase the steel sheet pile or to insert outward during the driving process).

② Adjustment for piles during the assembly.

For easier operation, the position of two sheet piles should be relatively higher than the other one. Moreover, the assembly should be close to the corner pile (generally 4-5 pieces from the corner pile). If there is a gap in the distance, an appropriate amount of adjustment needs to be made. To prevent the two piles that are not in the same plane, it is necessary to adjust the direction of the corner pile in time, so that one side of the lock is parallel to the opposite steel sheet pile.

3.1.3 Control of the driving process

In the driving process, there is a large gap among locks of steel sheet pile, and the top always tilts away from the first steel sheet pile. Therefore, for every four or five steel sheet pile, the inclination of steel sheet piles should be controlled within 1% by plumbing method. Also, an adjustment is required if the deviation exceeds the limit (Adjustment should be careful to avoid affecting the insertion of a steel sheet pile). If the soil is too hard to correct the deviation, the pulley is a good choice for correcting the deviation.

3.1.4 Enclosing purlin and support

There are two layers of enclosing purlins and support in each foundation pit, and four 2.5m×2.5m corner braces are installed at the four corners of each layer. The elevation of enclosing purlin on the first layer is 2m, and that of the second layer is 0 m. The enclosing purlin and diagonal bracing apply 32b channel steel, and 2.5m×2.5m angle brace is arranged in each corner. The bracing is arranged in the direction perpendicular to the long side of the support. The depth of foundation pit reaches 0.9m (elevation 1.8m) below the top of the steel sheet pile in the first excavation. In this position, double block 32B channel steel and steel sheet pile are welded to form the first enclosing purlin around the inner side of the cofferdam. For the second excavation, the depth of foundation pit reaches 2 m, and double block 32B channel steel and steel sheet pile are welded to form the second enclosing purlin.

There are a variety of factors that affects the driving process. If the lateral straightness of the cofferdam is poor, there will be a large gap between the enclosing purlin and steel sheet pile after installation. To prevent cofferdam deformation, all space between enclosing purlin and steel sheet pile is welded with steel plate pad. Also, the four corner joints of cofferdam are protected by welding 10mm steel plate. Electrical welding is used to install enclosing purlin, and full welding is required during construction.

3.1.5 Excavation and sealing of concrete caps

The ordinary shovel is used to excavate above the elevation of the first enclosing purlin. Then, for the rest of the excavation, long arm shovel is used, and manual bottom cleaning is required when 20cm away from the base to avoid disturbing the base soil. The earth pile is placed 8m away from the foundation pit, and the height of the pile is no more than 1.5m. Except the earthwork used for backfilling, the rest of it should be shipped out in time. During the excavation of the foundation pit, drainage ditch and water-collecting well shall be set up in the foundation pit. A sewage pump is arranged diagonally on the cofferdam (support) to drain the water inside the cofferdam (support). The pump should pump water (mainly groundwater) based on the construction requirements to ensure that the excavator works normally. After clearing the foundation pit, the following step is to trench drainage ditches around this pit and set the collecting well at the diagonal of cofferdam (support). During the construction of the cap, the sewage pump is used to draw water in the cofferdam (support).

After the completion of the excavation, it is necessary to clean the debris and loose ground in the base immediately, and the water in the base shall be drained. Then, the final step is to pour the cap and seal the bottom concrete.

3.2 Backfilling of the cap and removing the enclosing purlin support

After pouring the cap, the next step is to remove the formwork, following by backfilling earthwork and pouring the first column.

The sequence of backfilling earthwork and removing enclosing purlin:

Backfilling earthwork to the top of the cap and below the enclosing purlin of the second layer

Removing the enclosing purlin of the second layer

Setting the formwork and pouring the concrete for the first column of the erecting mould

Backfilling the second layer of earthwork

Removing the enclosing purlin of the upper layer. Backfill must be rammed in layers. The lower earthwork is rammed every 60cm. In the backfilling process, the side of the cap shall not be pushed by soil, and the mechanical equipment shall not collide with Lassen steel sheet pile to avoid deformation.

3.3 Lassen steel sheet pile removal

Sheet piling is withdrawn by the vibratory hammer. After the foundation pit is backfilled, steel sheet pile shall be removed for reuse. Before removing steel sheet piling, the method sequence, time and soil hole treatment should be carefully studied.

4.0 Conclusion

As temporary support structure for cofferdam construction of deep foundation pit of the bridge, Lassen steel sheet pile is easy to construct. Also, the requirements for construction equipment is not strict, and construction instruction is easy to follow. Moreover, the most important is that the sealing between plates is excellent, and the effect of water resistance and soil retaining on the cap is quite obvious. All in all, it is worth popularizing in the construction of deep foundation pit of the bridge.