Improved Construction Technology of Steel Sheet Pile Cofferdam Based on Monitoring Data

1.0 Introduction

In recent years, steel sheet pile has been more and more used in cofferdam construction of bridge pier because of its advantages of reusable, material saving and cost-saving. For the traditional steel sheet pile construction process, the first step is to insert steel sheet piles and then set up support as well as pumping a layer of water. This construction process undoubtedly leads to a massive displacement of steel sheet pile. The construction procedure of steel sheet pile cofferdam for the central pier cap of Jiaomen Waterway Bridge of Huanglan Expressway in Panyu, Guangzhou is quite different from that of the traditional procedure. In this project, five layers of the inner support frame system are welded and assembled on the water surface, and then lowered to the design position. The following step is to insert and drive steel sheet piles, which significantly shortens the time of pumping water and assembling support in layers. Therefore, it reduces the exposure time inside the cofferdam and improving the safety of the project. At the same time, the monitoring data analysis shows that the process can control the deformation of steel sheet pile, which has a useful reference for similar projects.

2.0 Project overview

The length of Jiaomen Waterway Bridge in Huanglam expressway, Guangzhou, is 1,043m.

It can be divided into two parts: the main bridge and the approach bridge. The main deck is arranged in two parallel bridges, with the full width of 40m. The width for the single bridge is 19m. The bridge is designed with four central piers, and the foundation of the main pier is high pile cap. The dimension of this type of caps is 17m×10.5m, and its thickness is 4.0m.

Moreover, its top elevation is 3.1m, and the bottom height is 7.1m. According to the geological survey report of this construction site, the riverbed is covered with 12.5~7.0m medium silt, 21.2~7.8m silt, and 31.2~5.9m silty clay. In Jiaomenkou, the mean high tide level is 6.2m, and the mean low tide level is 4.3m.

3.0 Cofferdam system

The lowest navigable water level of the bridge site is 3.79m, and the highest navigable water level is 7.3m. Four central piers are located in Jiaomen Waterway, and the main pier foundation consists of six Ø2.5 pile groups, which support mass concrete pile. The bottom of this cap is located about 4.5m below the riverbed. This construction adopts steel sheet piles cofferdam system with the plane size of 20.05m×12.76m, which is formed by 24m long Lassen steel sheet pile. The designed top elevation of steel sheet pile is 7.3m. The initial water level of the construction site is 6.5m. The mud level is -2.7m. The first, second, third waist beams are located at 6.0m, 3.0m, and ±0.0m, respectively. For the fourth and fifth waist beams are in the range from -2.0m to -4.0m.

4.0 Key points of construction

In the construction process of traditional steel sheet pile cofferdam, the working platform and guide casing are firstly arranged. Then, the steel sheet pile is driven. The arrangement of support and pumping are followed until the water is pumped to the end. The steel sheet pile has undergone an absolute displacement when each support is arranged, and the displacement is relatively large after pumping water to the end. The depth from the first waist beam to the bottom of the cofferdam in this project is 13.6m. Under the traditional construction procedure, there is a need to set up six layers of support, and the vertical spacing between each layer is relatively small. It will bring inconvenience to construction. In addition, the process to set up six layers of support is very time-consuming, and pumping in a foundation pit is always at high risk. In order to shorten the work period and reduce the construction risk, this project breaks the traditional construction process by first arranging the internal support frame system on the water surface and lowering it to the design position. In this plan, the next step is to insert and drive steel sheet piles.

Under this improved construction technology, only five inner support layers are required to meet the safety requirements. After fixing the five-layer support frame, the water is pumped out in the cofferdam. Compared with the traditional construction procedure, the displacement during the pumping process is greatly reduced, which helps to control the total displacement of steel sheet piles. In addition, the construction process adopts the method of pumping water to the end in a single time. This construction method reduces the time used in pumping water, which will take about five days. After that, the concrete is poured in cofferdam and cap, and the exposure time in the cofferdam is greatly reduced.

In this project, four steel jackets in the corners of each cofferdam are used as a load-bearing structure. Brackets are inserted where the steel jackets are 0.5m above the water surface, and the working platform is arranged. Then, the fifth waist beam is hung at the top of jack through the finished deformed bar. Then, 2m high upright is welded on the fifth waist beam and then connects the fourth and third waist beam. After that, the brackets can be dismantled. Through the use of four jackets, these three layers of the inner support system are lowered to 0.5m above the water surface. The following step is to set up the second and first layer inner support system and drop them. The vertical spacing among these five layers is 3m, 3m, 2m and 2m, respectively. After all of these five support layers are lowered to the designed position, levelness and inclination of the support need to be adjusted.

5.0 Comparison of two different working procedures

Under the traditional construction procedure, there will be six layers of inner support. It can be divided into eight working operations, as shown below:

- Install the first layer of support, insert steel sheet pile, and pump water to 0.5m below the second layer of support.

- Install the second layer of support, and pump water to 0.5m below the third layer of support.

- Install the third layer of support, and pump water to 0.5m below the fourth layer of support.

- Install the fourth layer of support, and pump water to 0.5m below the fifth layer of support

- Install the fifth layer of support, and pump water to see the bottom of the foundation pit

- A 2m high cap is poured by concrete, and the space between cap and steel sheet pile cofferdam is filled with fine sand.

- Dismantle the fifth layer of support

- Continue to pour the 2m high cap, and the space between cap and steel sheet pile cofferdam is filled with fine sand.

According to the calculation of traditional construction procedure, this cofferdam is equipped with six internal supports. In order to compare and analyze the different influences of the process in this paper and the traditional method on the displacement and internal force of the cofferdam, the following calculation is carried out for two different construction procedures when there are five layers of support in this cofferdam.

Cofferdam can be divided into eight working conditions according to the traditional process construction: 1. Install the first support, insert steel sheet pile, pump water to 0.5m under the second layer support, install the second support, pump water to 0.5m under the third layer support, and pump water to 5m under the fourth layer support; 2. Install layer four support. 5. Install the 5th layer of support. 6. Pour 2m cap, and backfill fine sand between cap and steel sheet pile cofferdam; 7. Remove the 5th layer support; 8. Continue to pour 2m cap, and backfill fine sand between cap and steel sheet pile cofferdam. Based on the research of Lu Peiyan, the process of adding bracing is simulated by the method of adding virtual tension.

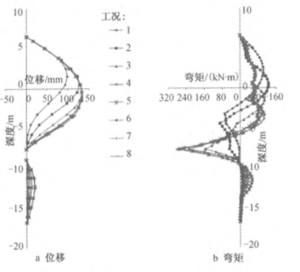

- Figure 1 The displacement and bending moment in the traditional construction

- Figure 2 The displacement and bending moment in the cofferdam project

The calculation results of the displacement and bending moment in the traditional construction process are shown in Figure 1. This Figure also illustrates that most displacement occurs in the first four working operations, and the displacement in the last four work operations are relatively small. If only five layers of support are set, and the traditional construction process is adopted, the displacement and bending moment during pumping is huge. Under this case, the maximum displacement is 134ram and the maximum bending moment of 292kN·m.

The construction process of cofferdam in this project is different from the traditional. Firstly, the internal supporting frame is made well, and then the steel sheet pile is inserted and closed. Then, water is pumped from the pit till the bottom of the pit is visible. In order to facilitate comparison with the traditional construction process, work operations in this method are consistent with that in the conventional process. The difference is that all supports in this method have been set up before cofferdam pumping. The calculation results of displacement and bending moment are shown in Figure. 2.

As can be seen from Figure 2, the displacement and bending moment of this project are significantly reduced compared with the traditional process. The maximum displacement is 26mm, and the maximum bending moment is 116kN·m. It can be seen that this construction procedure has a better performance in controlling deformation and bending moment.

6.0 Conclusion

Through the design, calculation and analysis of steel sheet pile cofferdam of the main pier cap of Jiaomen Waterway Bridge of Huanglan Expressway, Guangzhou, the following conclusions are drawn:

- Compared with the traditional steel sheet pile cofferdam construction process, the construction process of this project can avoid the problem caused by that steel sheet pile is not set up until deformation occurs in the traditional method. It plays a functional role in controlling the displacement and bending moment of steel sheet pile, and dramatically shortens the time of pumping (dredging) in cofferdam, as well as ensuring the safety of the whole cofferdam construction.

- From an economic perspective, this technology saves one layer of internal support, which shortens the construction period and reduce the rental funds of steel sheet pile.

- During the construction process, it is very likely to happen that steel sheet pile and ring beam do not fit each other, which is adverse to control pile deformation. If the displacement of steel sheet pile needs to be managed effectively, the verticality and precision for the insertion of steel sheet pile must be improved.