Construction Technology of Lengthy Steel Sheet Pile for Luneng Wharfs in Luoyuan Bay

1.0 Project overview

Luoyuan Bay is located in the northeast coast of Fujian province and adjacent to Sansha Bay in the north. Luoyuan Peninsula and Huangqi Peninsula surround this bay, and it looks like a fallen gourd. It is one of the best harbour-waters in northeast Fujian, and the total area for this bay is 179.56 km^2.

1.1 Meteorological conditions

The direction of a strong wind is west-northwest, and the course of the prevailing wind is south-southeast. The average wind speed for many years is 2. 2 m/s, and the average annual precipitation is 1,649.5 mm per year. For the detailed information on temperature, the average yearly temperature is 19℃. The maximum temperature is 39.5℃, and the minimum temperature is 3.9℃. The average number of days with the maximum daily temperature higher than 35℃ is 9.6 days.

1.2 Hydrological conditions

Tides in the construction site are normal semidiurnal tide. The mean high tide is 4.99m, and mean low tide is -0.15m. The mean range of tide in this location is 5.14m. The maximum velocity of flood tide is 0.82m/s, and the maximum speed of the ebb tide is 0.97m/s. The maximum wave height, H4 %, is 3.0m, and its wave direction is south-west. The average sediment concentration is 0.0326~0.0484 kg/m3.

1.3 Geological conditions

From top to bottom, there are grey silt, grey-yellow clay, grey-yellow gravel, grey clay, broken gravel-mixed clay layers in this construction site. Bedrock is granite formed in Yanshanian. According to the degree of weathering is divided into wholly-weathered rock and strongly weathered rock.

1.4 Position and type of steel sheet piles

The steel sheet piles used in this project are 94 composite BOX bedrock piles and 194 composite BOX retaining piles. For these 194 piles, there are two different lengths, which are 43.5m and 38m, respectively. There are two types of AZ steel sheet piles, AZ26 and AZ38-700. AZ38 breaks through the clay interlayer to the seventh soil layer — the mixture of clay and gravel.

2.0 Construction technology

The first step is to define the rough location for the steel sheet pile, and the original guide casing is set, as shown in Figure 1. This guide casing uses double H-beam walings, and No.12 structural steel and ø8 steel pipe are welded to be the overall frame structure. Also, Ø700 mm temporary steel pipe piles support them.

2.1 Construction process:

- Hoisting piles

- Insertion of the foreshaft

- Manual adjustment of the horizontal position through guide casing and limiting stopper

- Observation of perpendicularity

- Driving piles to soil level and Stabilizing piles(Pile frames must be vertical to the ground level)

- Set pile cap (It must be perpendicular to the ground level)

- Pressing piles (The original plan is to use vibration hammer first but to speed up the construction progress, pile hammer is used)

2.2 Specific construction method:

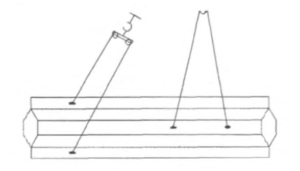

Guide casing is used for positioning steel sheet pile and control the inclination angle of steel sheet piles. The height of the guide casing is determined by the elevation of the pile top. The size of this guide casing is larger than that of BOX pile, so there isis a margin about 1m, which is used for a slight adjustment. In the construction, the guide casing for the first positioning pile is a double guide frame, and the slope for this is 20:1, meeting the requirement of the design. Suspension centres are arranged, as shown in Figure 2.

Figure 1.The original guide casing Figure 2. The arrangement of suspension centres

3.0 Precautions during the construction process

During steel sheet pile construction, the first pile is the reference pile for the rest of the piles, and its position must be accurate. The specific method is as follows:

After passing through the second layer of guide casing about 20cm, there is a need to measure the pile by the use of admeasuring apparatus. This process is to check whether the slope of the pile’s position is 20:1. After confirming it is correct, use the limiting stopper to lock both sides of the pile. In lowering process of piles, it is necessary to pay attention to whether the piles is close to the upper and lower layers of the guide casing. The use of a ruler to monitor the distance between the lock and guide casing helps to ensure the pile does not twist. The following pile is inserted into the lock of the previous pile, and slide down smoothly along the lock. After sliding down about 10cm, the pile stops moving. Then, the next step is to twist the pile to the right position manually. Under the use of locator card, the pile is locked, and then the lowering process starts again.

- According to the height of the tidal level at that time, judge whether the pile enters the mud surface. In the process of lowering the pile, it needs to judge whether the steel sheet pile meets obstacles at any time. For facing obstacles, the vibratory hammer is required for help, or diesel hammer is used to press the pile over the barriers. During the process of piling, reinforcing steel bars are added to ensure the stability of the surface layer.

- The angle of soil nail wall should be 45° ~ 65°. In this range, it can help to save investment and keep safe. A large number of engineering projects following this principle have also achieved excellent results.

- In the construction process of soil nailing wall, the treatment of aquifer is the critical procedure. Due to the effect of geological conditions, even if precipitation measures are adopted, a certain amount of groundwater remains between two impermeable layers. In the process of foundation pit excavation, quicksand forms between two waterproof layers, leading to collapse somewhere in the foundation pit. In this case, it is better not to dig through the waterproof layer(1~2m) at once. The next step is to bind the mesh of the surface layer quickly, and a layer of shotcrete mixed with an accelerating agent is sprayed on the surface. When the concrete has a particular strength, a net made of steel bars are set up and connected with transverse steel concrete. After the completion of soil nail construction, sufficient drainage holes should be arranged in the horizontal direction of the surface layer. It helps to eliminate the residual water inside, reducing the earth pressure and accelerating the consolidation of sand and soil.

- In Caofeidian, due to different geological conditions, there is a large amount of sandy, silty clay in different depths. Although this soil layer has an adverse influence on the dewatering effect, it is beneficial to the stability of the soil mass. This is caused by the considerable cohesion and internal friction angle of the sandy, silty clay. With the full consideration of the properties of the soil layer, optimizing the soil nailing wall is required, which can save the cost and ensure safety.

- Soil nailing wall technology is suitable for application in this area. Due to the fact that most of the geology in this area is backfill sand, rainwater penetrates the ground evenly in the case of rainfall. It basically does not form surface runoff and has a little damage to the soil nailing wall. During the construction process, the edge of the foundation pit should be made slightly higher than the surrounding area to prevent rainwater from flowing into the interior. Drainage ditches are set at the bottom of the foundation pit to prevent sudden heavy rain from soaking the bottom of the foundation pit.

- During construction, it is necessary to pay attention to the observation for deformation and settlement of foundation pit, as well as making the accurate judgement of its stability in time. The surface cracks around the foundation pit should be carefully analyzed. According to the theory of slope stability of foundation pit, a few cracks around the soil nailing wall and foundation pit have a limited impact on the stability of the foundation pit. However, cracks occurring 5-6m away from the edge of the foundation pit or beyond have a more significant effect on the stability of the foundation pit. Therefore, careful observation is essential, and corresponding treatment measures should be taken.